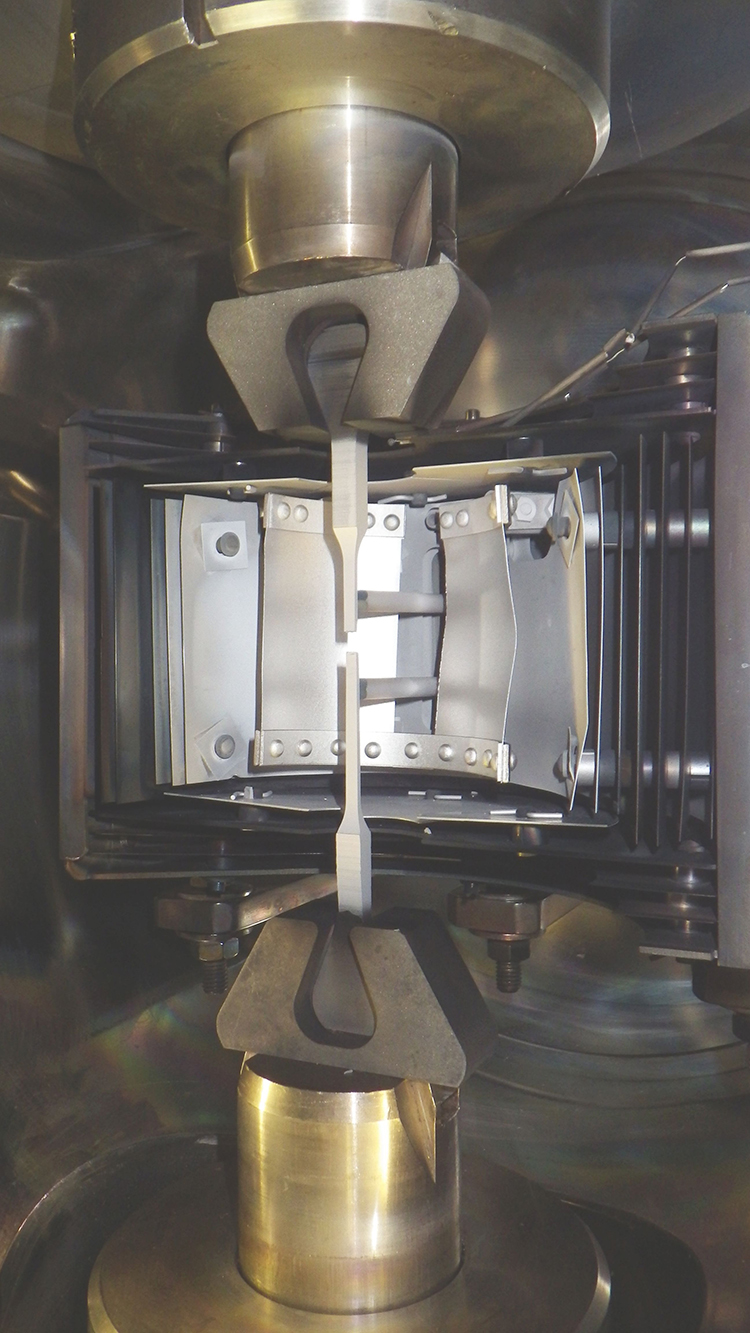

Mechanical Testing

The aim of mechanical testing methods is to determine mechanical parameters as input variables for component design and simulations. It is only the knowledge of mechanical parameters and their scattering that allows the safe, economical and technically sensible use of materials. An innovative application of newly developed materials is impossible without the knowledge of elastic and plastic deformation and its limits.

While test standards and standardized sample shapes guarantee reliable results for classic materials, materials in the development stage often require adapted sample shapes, sample holders and test procedures. The team provides many years of experience in materials testing for research and development work in the field of materials testing.

The mechanical test laboratory of Fraunhofer IFAM Dresden is accredited by the DAkkS for tensile and compression tests at room temperature. The testing machines and strain measurement systems are calibrated annually, and for more than 5 years the highest accuracy class 0.5 has always been achieved.

Research Areas

- Measurement of mechanical parameters with tensile, compression and bending tests

- Sample preparation for tensile, compression and bending tests

Our Services

- Determination of mechanical parameters in tensile tests according to DIN 10002-1 (RT) and DIN 10002-5 (up to 900°C)

- Determination of the mechanical parameters in high-temperature tensile tests (in-house procedure up to 1,600°C)

- Determination of mechanical parameters in compression tests according to DIN 50106 (RT)

- Determination of bending properties (three-point bending) according to DIN ISO 178 (RT)

- Sample Preparation

Fraunhofer Institute for Manufacturing Technology and Advanced Materials IFAM

Fraunhofer Institute for Manufacturing Technology and Advanced Materials IFAM